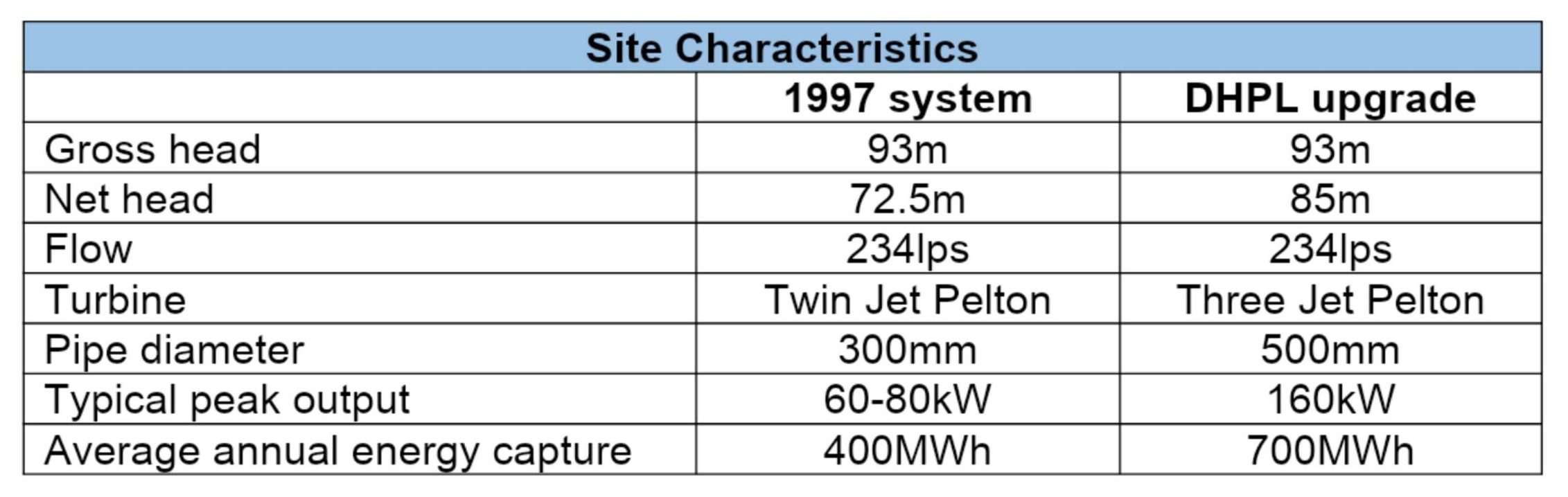

With a storage capacity of 24,995m³, Cynwyd Reservoir was built in 1923 to supply a water treatment facility in Cynwyd village. In 1997, following the closure of the water works, the site infrastructure was re-purposed to supply a hydroelectric power turbine. This system was purchased by DoPower Ltd, part of the DHPL Group, in 2016.

Following an initial period of operation, DHPL designed and installed wide-ranging improvements, resulting in higher peak power, increased energy capture, and improved reliability.

Improvements were generally grouped into four distinct projects: pipeline, turbine, control, and intake screening:

1: Pipeline

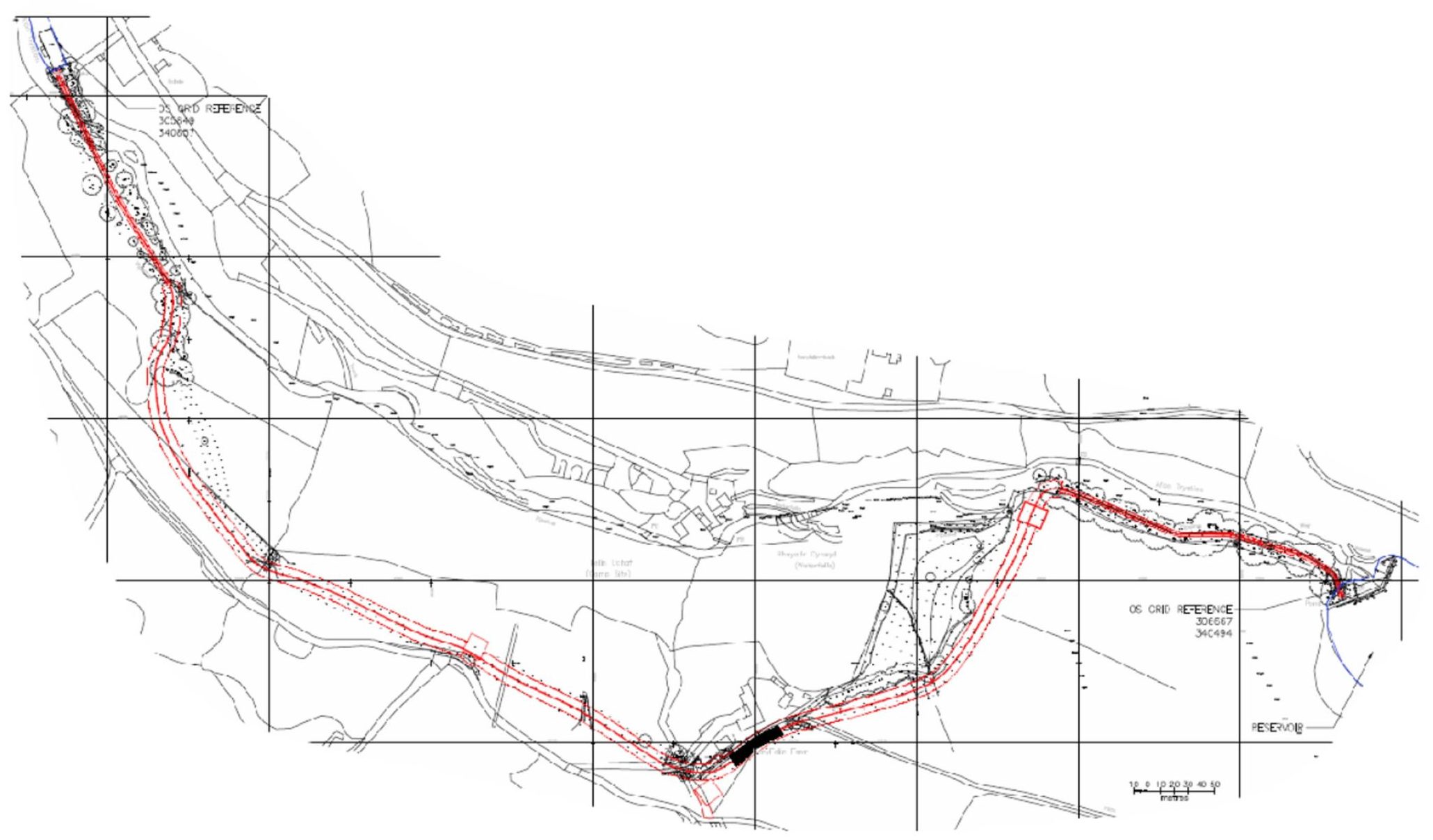

The original pipeline used a 300mm concrete-lined cast iron pipe. This was too small for the licensed turbine flow, resulting in unacceptable pressure loss. The pipeline was also positioned in areas with poor installation and maintenance access, including five river crossings – pipe bursts and river damming had previously been suffered at these locations.

DHPL’s solution took a slightly longer route, avoiding four of the river crossings and allowing for safe and environmentally sympathetic installation. The new pipe is also larger diameter, significantly reducing pressure loss experienced at the turbine, thereby increasing generating potential.

2: Turbine

The 1997 turbine (left, below) suffered several maintenance problems: one of the two spear jets was not operational; the main isolation valve frequently failed; the generator was inaccessible for servicing; and the actuation system had problems.

These were all resolved by the installation of a new turbine (right, above) in 2020:

The new turbine offers increased power output and has proven to be reliable.

3: Control

The new turbine is controlled by a bespoke DHPL control panel. This provides on-site touch-screen control as well as remote access facilities, allowing the system to be effectively monitored and controlled from our base in Derbyshire.

The controller is also linked to DHPL’s Logging Website, which harvests control data at 10-minute intervals. This produces a detailed database to support optimisation, fault diagnosis and early-warnings, and regulatory compliance.

4: Screening

The intake screen is normally mostly submerged, and must operate throughout a range of reservoir water levels. By the time of DoPower’s ownership, the 1997 screen was in a poor condition and was difficult to clean with any efficacy. DHPL designed and installed a new screen with a larger surface area to improve flow transfer; narrower bar spacing to better protect the hydro and aquatic life; and improved maintenance access.

This website is operated by Derwent Hydroelectric Power Ltd a company registered in England under company registration number 2227448 and whose registered office is situated at Sir Richard Arkwright’s Masson Mills, 41 Derby Road, Matlock Bath, Derbyshire, England, DE4 3PY. and whose VAT number is 507741254.

© Derwent Hydroelectric Power Ltd